NONWOVENS WITH AQFRESH™ TECHNOLOGY – PROVEN TO SIGNIFICANTLY REDUCE ODOURS – TO BE INTRODUCED AT INDEX23

At INDEX23 Geneva (stand 4119), Aqdot will be presenting nonwovens incorporating AqFresh™ technology, produced using typical industrial processes. They will also present the results of a study of their odour elimination performance.

For a free copy of our AqFresh Nonwoven Industrial Scale Up White Paper, outlining the study and results in detail, complete the form further below.

The TECHNOLOGY

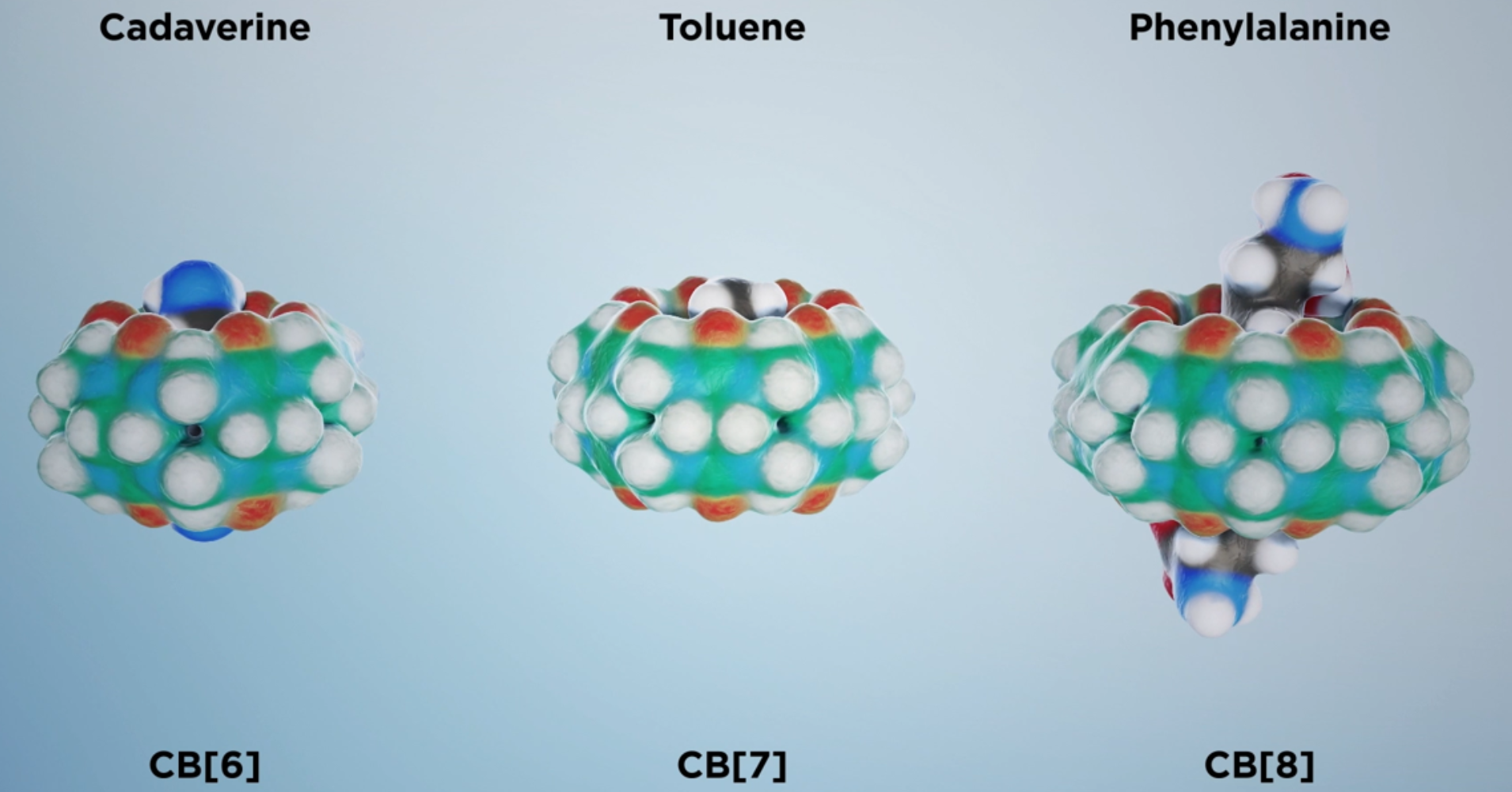

The unique patented technology significantly reduces odours (such as urine, sweat and ammonia) and pollutants such as BTEX. It uses Cucurbiturils – barrel-shaped molecules with a hollow, hydrophobic cavity and polar portals – to capture & tightly bind a wide range of malodour & pollutant molecules.

AqFreshTM 3D VIDEO

ITS APPLICATIONS

This patented technology has a range of nonwoven applications including:

- Hygiene

- Health Care

- Home Care

- Automotive Interiors

- Filters

- Building Materials

It is proven to work in nonwovens applied using a range of methods:

- Compounding/extrusion into fibres

- Finishing via kiss roll or padding/spraying

METHODS OF INCORPORATION INTO NONWOVENS

Aqdot has worked with nonwoven manufacturers to carry out industrial production trials of nonwovens in order to assess its performance in application.

A range of typical nonwoven materials have been produced including:

- Polyester, Viscose & Spunbond Polypropylene 35-100gsm for hygiene topsheets & ADL, and healthcare

- Filtration Felt 4mm and Meltblown 15gsm

The AqFresh™ technology was incorporated into the nonwovens using a wide range of methods including:

- Compounding/extrusion into fibres

- Finishing via kiss roll or padding/spraying or dry impregnation

BINDING & DURABILITY ASSESSMENT

AqFresh™ incorporation was verified using a simple staining visualisation method and shown to be successfully bound to the nonwoven material. Its durability in nonwoven fibres was tested and demonstrated in washing resistance tests. Incorporation can also be delivered by use of an appropriate binder in the finishing treatment.

ODOUR PERFORMANCE ASSESSMENT

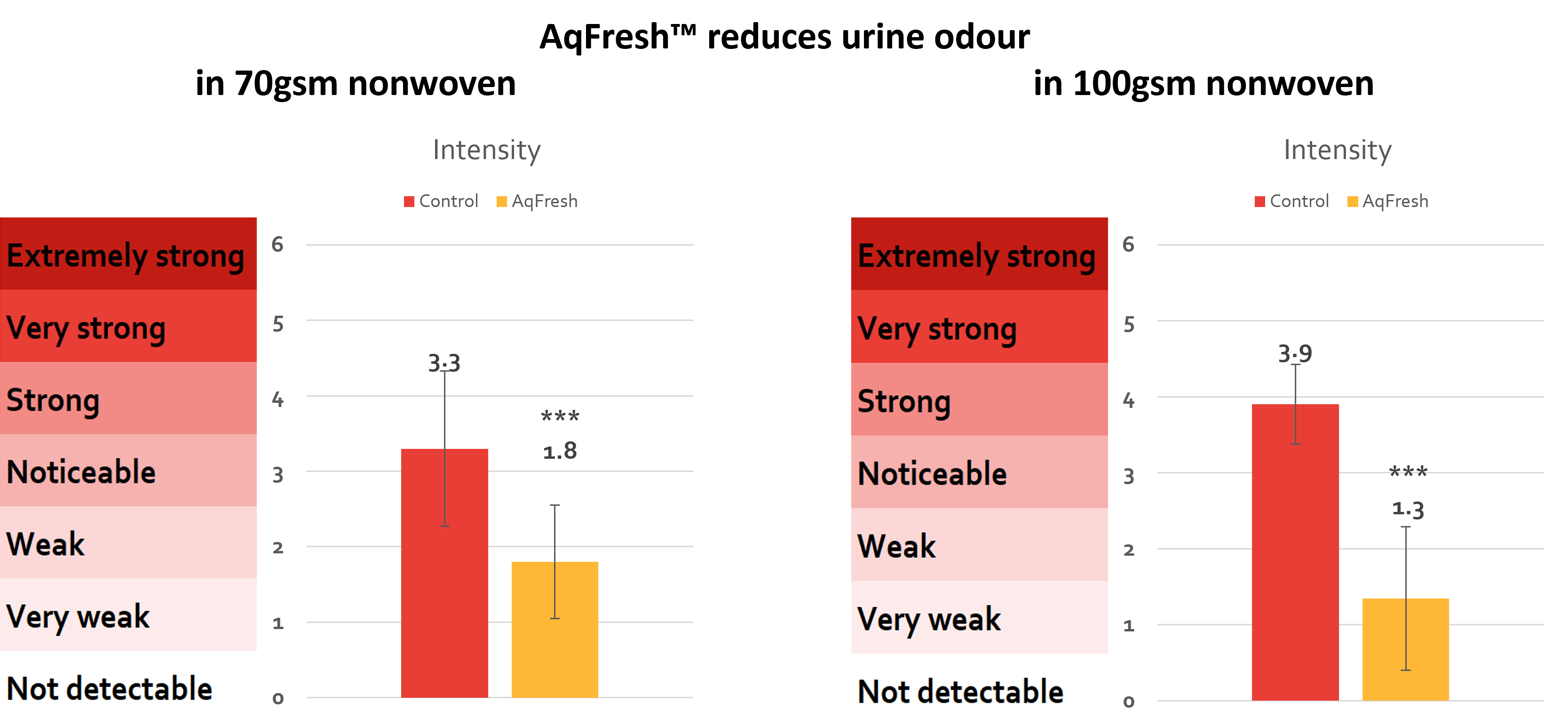

The odour elimination performance of the nonwovens with AqFresh™ was studied by an externally validated, trained expert sensory panel who assessed the malodours following ISO6658 and ISO8586:2012. Analytical testing – GC-MS-TD – was also used to analyse the amount of residual malodour molecules present.

CONCLUSIONS

AqFresh™ was proven to significantly reduce all the odours & pollutants tested in a wide range of nonwoven materials, incorporated via a variety of methods, and shown to have durable results. Here are the results of 2 typical nonwovens tested in the study:

For a free copy of our AqFresh Nonwoven Industrial Scale Up White Paper, outlining the study and results in detail, please visit us at INDEX23 stand 4119 or complete the contact form below with “AqFresh Nonwoven White Paper” in the subject.

.png)